unsereLeistungEN

Our products

- We produce for you ALP-prototypes

- We put you on disposal ALP-components for your own test trials

- We supply small series of ALPs

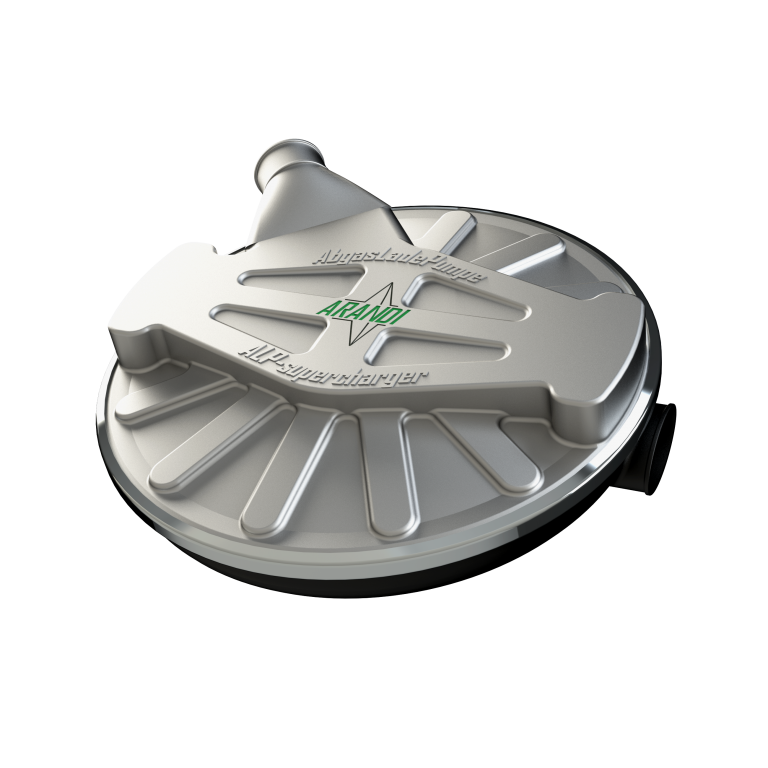

ALP-25 for engines with 100-300cc displacement

- The new ALP-25 generally is suitable for cylinder displacements between 100-150cc

- The ALP-25 has an outer diameter of 250mm and a total height of 60mm and mostly can be integrated into smaller vehicles without problems

- As well it is possible to cascade two ALP-25 to a double “D-ALP-25” for the application on 200-300cc engines

ALP-25 in a 125ccm scooter

- We have integrated the ALP-25 into a 125cc scooter, which is tested and optimized currently on our engine performance tester

- There is tested both a fuel saving engine version (downspeeding) on the performance level of the factory engine and a performance increased version to take advantage of the legal limit of 15hp (max. output for 125cc vehicles in EU)

- Beside optimized torque- and performance characters also mappings of specific fuel consumption are generated to demonstrate the potential of CO2-reduction

Results will be published soon!

Furthermore we supply other ALP-model series

- ALP-19 for engines of 50-70cc (Dia=190mm, Height=50mm)

- ALP-31 for engines of 250-300cc (Dia=310mm, Height=75mm)

- D-ALP-31 for engines of 450-650cc (Dia=310mm, Height=140mm)

Our Services

- We design ALPs individually for your engine

- We test and optimize in-house your engine on our performance tester with respectively without ALP

- We optimize the ALP-layout for your engine regarding torque characteristic and specific fuel consumption

- We optimize the ALP-layout corresponding your requirements

- We support you with the integration of the ALP into your vehicle respectively engine design

Performance tester

Our performance tester type (Amerschläger P4) we have modified hardly. The P4-performance tester is equipped with an eddy current brake. Engine tests can be executed as well with the engine coupled directly to the eddy current brake as indirectly by taking the performance at the rear wheel of the vehicle on the roller of the performance tester.

The performance tester can be controlled, as well manually as remote controlled including video monitoring.

Subsequent resarch we execute:

- Performance tests at the rear wheel for two-wheel-vehicles

- Direct performance test at the crankshaft of the engine (max. permanent load 50kW)

- Measurement of specific fuel consumption, torque, power, mean pressure, AFR, exhaust gas temperature, etc.

- Creation of mappings

- Tuning / optimization of customers engines with ALP-supercharger

- Continuous examination of engine / ALP-supercharger