What is the ALP-supercharger-technology

What is the ALP-supercharger-technology?

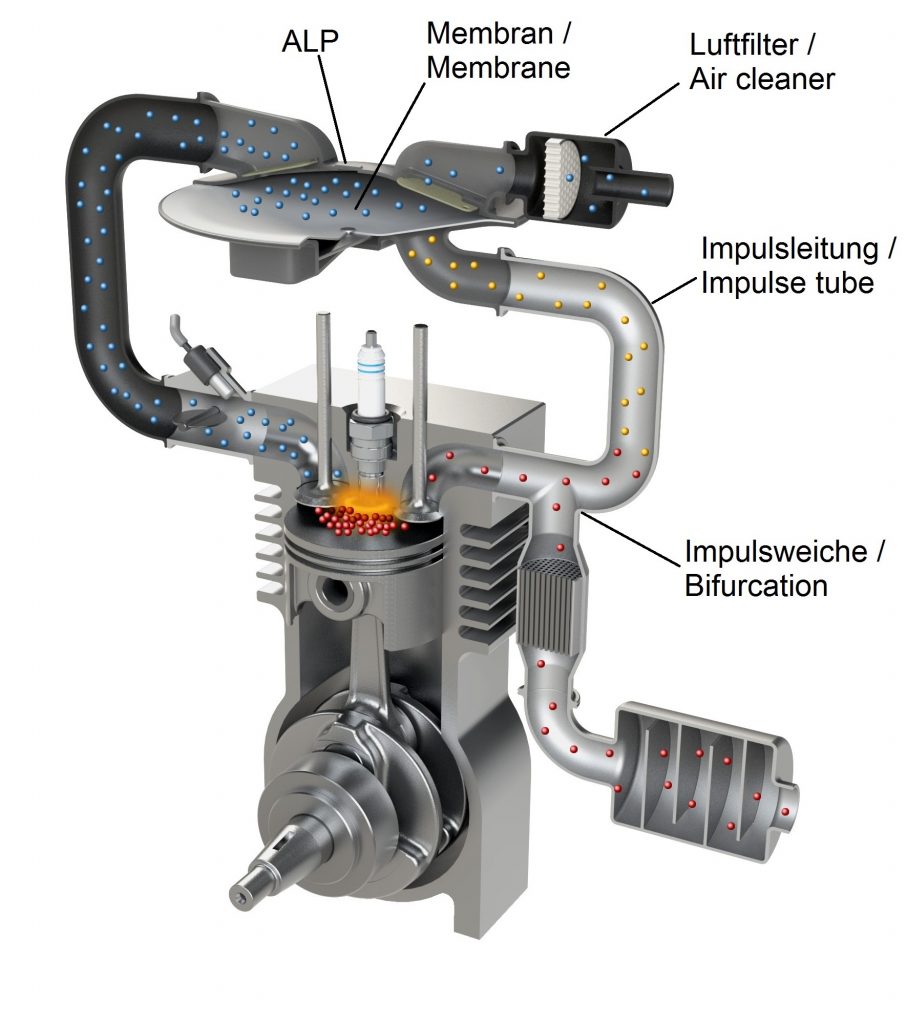

Operating principle of the ALP

- The ALP supercharger is a membrane pump that is driven by the pressure pulsations inside the exhaust gas system of the engine

- The ALP transforms the exhaust gas pressure energy into a pre-compression of fresh air

- The ALP is connected with the exhaust port of the engine via the bifurcation and impulse tube

- The bifurcation leads the exhaust gas pressure waves to the ALP, whereas the gas volume in the impulse tubing effects the thermal insulation

- The exhaust gas temperature can be hold permanently lower than 80°C inside the ALP by a suitable designed impulse tube

- After occurred energy exchange inside the ALP the exhaust gas flows backwards via the impulse tube to the bifurcation where it passes to the exhaust gas manifold (catalyst), the silencer and finally into the ambiance

- In the fresh air chamber of the ALP each compression shock pushes fresh air into the inlet manifold where it is storaged until the inlet valve opens

- Subsequent fresh air is aspirated from atmosphere when the membrane returns by a spring pre-load

- Reed valves control the fresh gas flow inside the ALP automatically

- The ALP works synchronously to each combustion cycle of the engine

- The ALP is a passive running system that doesn´t need any control mechanism

- An intercooler can be dispensed in almost any applications, because the charging pressures are settled around 1,5 bar absolute

Video animation of the ALP combined with a single cylinder engine

Characteristics of the ALP

- Increase of torque and power up to 45% compared with naturally aspirated engines

- Reduction of the specific fuel consumption up to 25% by means of abstinence of full load enrichment, positive work of load exchange, down-sizing and down-speeding

- One ALP for each cylinder

- Excellent transient response at load changes without any turbo lag

- Separated fresh and exhaust gas conducts

- No negative influence on the starting behaviour of the engine

- Totally free of maintenance, no lubrication needed

- Mostly made of plastic materials

- Low additional weight (0,8-1,5 Kg)

Background / motivation for the ALP development

- By means of the ALP-technology worldwide it succeeded the first time to develop a low-cost supercharger technique for small vehicle engines that is able to be industrialized.

- Primarily target markets are two-wheeled vehicles which at the time are without fail naturally aspirated.

- These engines with a displacement of 50-650cc have a potential for the reduction of specific fuel consumption in the range of 15-30% by using the exhaust gas energy.

- Annually about 100 Million vehicles off this category are produced worldwide.

- For these type of engines the well known turbo- and compressor supercharger technology is not suitable for physical or rather economical reasons. So the ALP-technology has no direct competitor-technologies at the time.

- The ALP supercharger is producible for about 10-15U$ in mass production. Almost all components are made from plastic materials or sheet metal.